FRP Grating Brisbane - Durable Fibreglass Reinforced Plastic Solutions | Treadwell Group

Choose Treadwell Group for Superior Corrosion-Resistant FRP Grating Solutions in Brisbane, Queensland

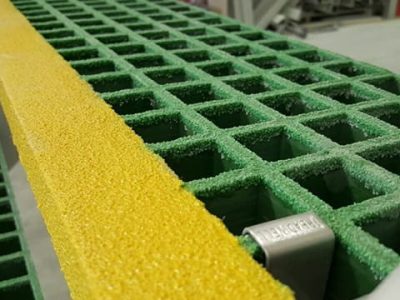

We understand that when you’re looking for FRP grating solutions, corrosion resistance isn’t just a feature—it’s absolutely crucial for your project’s long-term success. That’s why we’ve dedicated ourselves to manufacturing and supplying premium fibreglass reinforced plastic grating that stands up to Australia’s harshest environmental conditions. Our corrosion-resistant FRP grating delivers unmatched durability in chemical processing facilities, marine environments, wastewater treatment plants, and industrial applications where traditional materials simply can’t perform.

You’ll benefit from our extensive operational network that guarantees reliable delivery and support throughout Brisbane, Queensland and beyond. We’ve built our reputation on providing FRP grating solutions that resist acids, alkalis, salts, and other corrosive substances that would quickly deteriorate steel or aluminum alternatives. Our products maintain their structural integrity and appearance even after years of exposure to aggressive chemicals and humidity, giving you the peace of mind that comes with a truly long-lasting investment.

When you choose our corrosion-resistant FRP grating, you’re not just getting a product—you’re getting a complete solution backed by our technical expertise and nationwide support network. We work closely with engineers, contractors, and facility managers to specify the right grating configuration for each unique application, guaranteeing ideal performance in your specific corrosive environment. Our team understands the critical importance of selecting materials that won’t compromise safety or require frequent replacement, which is why we’re committed to delivering FRP grating solutions that exceed your expectations for both performance and longevity.

About Treadwell Group

Treadwell Group offers premium FRP (Fibreglass Reinforced Plastic) grating solutions designed for demanding industrial and commercial applications across Brisbane, Queensland and throughout Australia and New Zealand. With over 30 years of expertise in FRP technologies since 1994, the company delivers corrosion-resistant, lightweight, and non-conductive grating systems that provide exceptional durability and anti-slip properties while requiring minimal maintenance. Their extensive FRP grating portfolio spans multiple product lines including Exduro™, Safe-Series™, SecurEX®, NatureTREAD™, and EcoEX™, engineered to meet the rigorous demands of diverse sectors including water and wastewater treatment, mining, oil and gas, utilities, rail infrastructure, and public works. Backed by a robust operational network of offices and warehouses, Treadwell Group’s FRP grating solutions combine advanced composite technology with proven performance to deliver long-lasting, cost-effective alternatives to traditional materials in environments where corrosion resistance and structural integrity are paramount.

- 30+ years FRP expertise

- Corrosion-resistant lightweight solutions

- Multi-industry proven systems

- Australia-wide delivery network

- Award-winning anti-slip technology

Ready to upgrade to corrosion-resistant FRP grating that'll stand the test of time? Let's discuss how we can solve your infrastructure challenges today.

How Can We Help

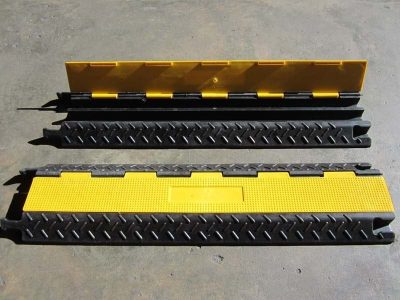

At Treadwell Group, we’ll provide you with high-quality FRP grating solutions that deliver exceptional durability, corrosion resistance, and lightweight performance for your industrial and commercial applications throughout Brisbane, Queensland. Our fibreglass reinforced plastic grating systems are engineered to withstand harsh environmental conditions while offering superior strength-to-weight ratios, making them ideal for walkways, platforms, drainage covers, and industrial flooring where traditional materials might fail or require frequent maintenance. We understand that you need reliable, long-lasting solutions that won’t compromise on safety or performance, which is why our FRP grating products are designed to resist chemicals, dampness, and UV exposure while maintaining their structural integrity for years to come. Whether you’re working on a new construction project or replacing existing grating systems, we’ll work with you to guarantee our FRP solutions meet your specific requirements and provide the cost-effective, low-maintenance alternative you’re looking for.

Why Us

When you’re looking for FRP grating solutions, we’re the team you can trust to deliver exceptional results that’ll stand the test of time. With over 30 years of experience since our establishment in 1994, we’ve perfected our FRP technologies to provide you with grating systems that are durable, corrosion-resistant, and lightweight – exactly what you need for demanding industrial applications. Our extensive range of product brands, including Exduro™ and Safe-Series™, means we’ve got the right FRP grating solution for your specific requirements, whether you’re in water treatment, mining, oil and gas, or public infrastructure. We serve Brisbane, Queensland, and beyond through our extensive network of offices and warehouses across Australia and New Zealand, ensuring you’ll receive reliable delivery and support when you need it. What sets us apart is our commitment to providing non-conductive, anti-slip FRP grating systems that require minimal maintenance, saving you time and money while keeping your operations running safely and efficiently.

Contact Now To Schedule Personalised Consultation

PROVIDING INNOVATIVE FRP SOLUTIONS

FAQs

What is FRP grating and why should we consider it for our project?

FRP grating is a structural flooring and platform solution made from fibreglass reinforced plastic that combines glass fibres with resin to create an incredibly strong yet lightweight material. We’d recommend considering FRP grating as it’s corrosion-resistant, non-conductive, and offers excellent anti-slip properties while requiring minimal maintenance. Unlike traditional steel grating, our FRP solutions won’t rust, conduct electricity, or deteriorate in harsh chemical environments, making them ideal for water treatment facilities, mining operations, and industrial applications.

How long does FRP grating typically last compared to steel alternatives?

Our FRP grating systems are designed to last significantly longer than steel alternatives, often 20-30 years or more depending on the application and environment. While steel grating may need replacement every 5-10 years owing to corrosion, our FRP products maintain their structural integrity and appearance for decades. We’ve been perfecting FRP technologies since 1994, and our experience shows that the durability of our grating solutions provides excellent long-term value, especially in corrosive environments where steel simply can’t compete.

What industries and applications do you typically supply FRP grating for?

We supply FRP grating across diverse sectors including water and wastewater treatment, mining, oil and gas, utilities, rail, and public infrastructure projects. Our grating solutions are particularly popular in chemical processing plants, offshore platforms, walkways, stair treads, drainage covers, and industrial flooring applications. We serve Brisbane and throughout Queensland with our extensive range of FRP products, and our multiple offices and warehouses across Australia and New Zealand guarantee we can support projects of any scale.

Can FRP grating handle heavy loads and what are the weight advantages?

Yes, our FRP grating can handle substantial loads while being up to 75% lighter than steel equivalents. This weight reduction doesn’t compromise strength – our grating maintains excellent load-bearing capacity while making installation faster, safer, and more cost-effective. The lightweight nature means reduced structural support requirements, lower transportation costs, and easier handling during installation. We’ll work with you to specify the right grating configuration to meet your specific load requirements and safety standards.

What maintenance is required for FRP grating systems?

One of the biggest advantages of our FRP grating is the minimal maintenance required. Unlike steel that needs regular painting, rust treatment, and potential replacement, our FRP systems typically only need occasional cleaning with standard detergents and water. There’s no painting, coating, or anti-corrosion treatments needed throughout the product’s lifespan. This low-maintenance characteristic, combined with our 30+ years of experience in FRP technologies, means you’ll save significantly on lifecycle costs while maintaining a safe, attractive installation.

HEAR WHAT OUR CLIENTS HAVE TO SAY

Treadwell is a professional company to deal with and delivered a quality product. After several years in a harsh environment, it continues to look as good as the day it was installed.

Extremely happy with materials and overall finished product… The value for money using Treadwell materials was the main draw card as we more than tripled the life expectancy of the design.

The company runs a tight ship when it comes to integrity of business ethics and quality of its products… I am confident that when measured against their competitors, we will find them to be our strongest partner in the FRP and engineered polymers space, on this continent.

AU

AU

NZ

NZ

UK

UK