Melbourne Substation

Melbourne Substation

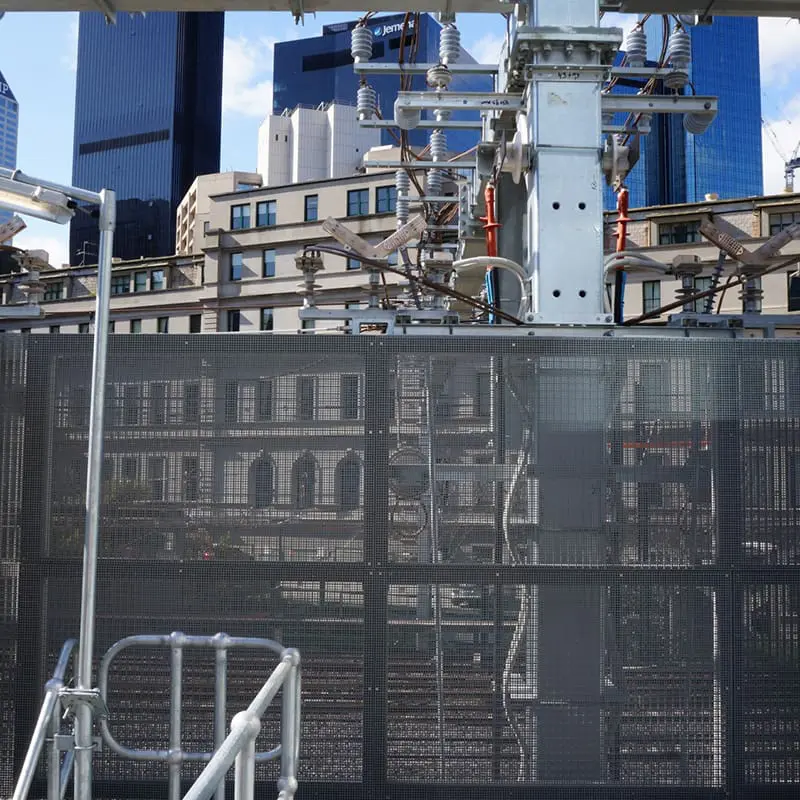

In order to maximise space and prepare for high capacity metro trains, a multi-storey substation was custom designed to be installed in Melbourne’s CBD. This would be situated on a narrow strip of land, and had to be constructed within a tight timeframe. Prefabrication technology allowed the substation to be built off site at the same time as the foundation being installed; this saved time and eliminated the potential for weather delays. Consisting of a team of contractors, communication and action had to be precise.

Treadwell was engaged to supply the FRP products for the structure and security perimeter.

Project Challenges

- It was a key consideration that the product be non-conductive. This was to ensure maximum safety for staff and public.

- Posts, rails and barrier mesh needed to be designed to withstand the wind load requirements of AS1170.

- The selected product had to be able to form a secure perimeter around the structure, proving a safe barrier against trespassing and various security concerns.

Project Information

Project Category: Utilities Infrastructure

Scope of Work: Supply SecurEX® FRP Solution

Treadwell Products :

- ArchitEX™ FRP Structural Profiles

- EX-Series® GratEX® FRP Micro Mesh Grating

- SecurEX® FRP Picket Fence System

Treadwell Solution

- Treadwell’s SecurEX® FRP fencing is suited to a wide range of rail applications, especially in areas where stray electrical currents are concerns.

- SecurEX® FRP Picket Fence is an anti-climb design, providing an added layer of security around the structure it protects. Easily installed on even and uneven ground.

- GratEX® FRP Micro Mesh grating was selected as it accommodates wind loading concerns while providing a barrier against debris or foreign objects.

- Being lightweight and easy to install, FRP is very manageable during construction.

- Given the nature of FRP, any system utilising it is virtually maintenance free, keeping maintenance costs to a minimum.

AU

AU

NZ

NZ

UK

UK