FRP Rebar Sydney - Durable Corrosion-Resistant Solutions | Treadwell Group

Hire Treadwell Group in Sydney, New South Wales for Lightweight FRP Rebar Solutions

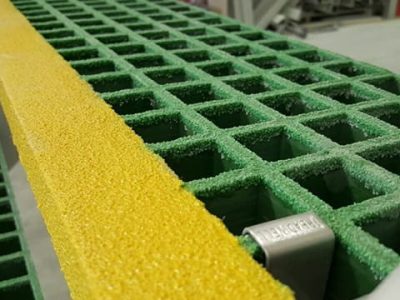

We understand that traditional steel rebar can weigh down your construction projects, literally and figuratively. That’s why we’ve developed innovative FRP rebar solutions that deliver exceptional strength while being significantly lighter than conventional reinforcement materials. Our lightweight FRP rebar systems make transportation, handling, and installation remarkably easier for construction teams across Sydney, New South Wales, reducing labor costs and project timelines without compromising structural integrity.

The beauty of our lightweight FRP rebar lies in its advanced fibreglass reinforced plastic composition, which achieves superior tensile strength at a fraction of the weight of steel alternatives. We’ve engineered these systems to be completely corrosion-resistant and non-conductive, guaranteeing your structures maintain their integrity over decades while requiring minimal maintenance. This weight reduction doesn’t just benefit your workers’ backs – it additionally reduces foundation requirements and overall structural loads, leading to more economical building designs.

When you choose our lightweight FRP rebar solutions, you’re investing in technology that transforms how reinforcement works in your projects. We’ve seen construction teams increase their productivity by up to 40% simply due to the fact that our materials are so much easier to maneuver and position. The anti-slip surface treatment we apply guarantees safe handling even in challenging weather conditions, while the lightweight nature means smaller crews can accomplish what traditionally required larger teams with heavy lifting equipment.

About Treadwell Group

Treadwell Group offers high-performance FRP Rebar as part of its extensive range of fibreglass reinforced plastic solutions, bringing over 30 years of expertise in FRP technologies to construction and infrastructure projects. This corrosion-resistant, lightweight reinforcement solution provides superior durability compared to traditional steel rebar, making it ideal for harsh environments across water and wastewater, mining, oil and gas, utilities, rail, and public infrastructure sectors. The FRP Rebar requires minimal maintenance while delivering non-conductive properties and exceptional longevity, supporting Treadwell’s core values of durability, corrosion resistance, and lightweight performance. Serving Sydney, New South Wales, and backed by multiple offices and warehouses across Australia and New Zealand, Treadwell Group guarantees reliable delivery and operational support for FRP Rebar installations, contributing to sustainable and long-lasting infrastructure solutions.

- 30+ years FRP expertise

- Award-winning corrosion-resistant solutions

- Lightweight, maintenance-free systems

- Serving Sydney’s major industries

- Australia-wide delivery network

Let's discuss how our proven FRP rebar solutions can strengthen your next project across Sydney and beyond – contact us today for a consultation that'll show you the durable difference three decades of expertise makes.

How Can We Help

At Treadwell Group, we understand that traditional steel rebar can be a major headache for your construction projects, especially when you’re dealing with corrosive environments or need to reduce structural weight. That’s why we’ve developed our FRP Rebar solutions to give you the durability and strength you need without the downsides of steel. Our fibreglass reinforced plastic rebar won’t corrode like steel does, which means your concrete structures will last longer and require less maintenance over time. We’ve additionally engineered it to be significantly lighter than steel, making it easier for your crews to handle and install, while still providing the tensile strength your projects demand. Whether you’re working on marine structures, parking garages, or any concrete application where corrosion is a concern, we’re here to help you build stronger, longer-lasting structures that’ll save you money and headaches down the road, and we proudly serve Sydney and the broader New South Wales region with these innovative solutions.

Why Us

When you’re looking for FRP Rebar solutions, we’re the proven choice with over 30 years of specialised experience in fibreglass reinforced plastic technologies since 1994. We’ve built our reputation on delivering durable, corrosion-resistant, and lightweight FRP systems that consistently outperform traditional materials while requiring minimal maintenance throughout their lifecycle. Our extensive range of trusted product brands like Exduro™ and Safe-Series™ demonstrates our commitment to innovation and quality, and we’ve successfully served diverse sectors including water & wastewater, mining, oil & gas, utilities, rail, and public infrastructure across Sydney, New South Wales and beyond. With multiple offices and warehouses spanning Australia and New Zealand, we’ve established a robust delivery and operational network that guarantees you’ll receive reliable support and timely project completion, making us your ideal partner for superior FRP Rebar solutions that won’t let you down.

Contact Now To Schedule Personalised Consultation

PROVIDING INNOVATIVE FRP SOLUTIONS

FAQs

What's FRP rebar and how's it different from traditional steel rebar?

FRP rebar is a composite reinforcement made from fibreglass and resin that we’ve been perfecting for over 30 years. Unlike steel rebar, our FRP rebar won’t corrode, rust, or conduct electricity, making it ideal for projects where durability and longevity are critical. It’s additionally significantly lighter than steel while maintaining excellent tensile strength.

Where can we use your FRP rebar products?

We’ve designed our FRP rebar for various applications across the sectors we serve throughout Sydney and New South Wales. You’ll find it perfect for water treatment facilities, marine structures, bridge decks, tunnels, and any concrete structure exposed to corrosive environments. It’s particularly valuable in mining operations, utilities infrastructure, and rail projects where traditional steel would deteriorate rapidly.

How much maintenance will we need with your FRP rebar systems?

That’s one of the biggest advantages we offer – our FRP rebar requires minimal maintenance compared to steel alternatives. Since it doesn’t corrode or rust, you won’t face the ongoing costs and disruptions associated with steel rebar deterioration. This low-maintenance characteristic has made it a preferred choice for our clients in water and wastewater applications.

What's the lifespan we can expect from your FRP rebar?

Our FRP rebar systems are built to last decades longer than traditional steel reinforcement. While steel rebar typically requires replacement or major repairs within 20-30 years because of corrosion, our corrosion-resistant FRP solutions can maintain their structural integrity for 75-100 years or more, depending on the application and environmental conditions.

How do we specify and install your FRP rebar products?

We’ll work with your engineering team to guarantee proper specification based on your project requirements. Our FRP rebar installs similarly to steel rebar but with some important differences – it can’t be bent on-site like steel, so we’ll pre-fabricate shapes to your specifications. We’ll provide detailed installation guidelines and support throughout your project, backed by our extensive delivery network across Australia and New Zealand.

HEAR WHAT OUR CLIENTS HAVE TO SAY

Treadwell is a professional company to deal with and delivered a quality product. After several years in a harsh environment, it continues to look as good as the day it was installed.

Extremely happy with materials and overall finished product… The value for money using Treadwell materials was the main draw card as we more than tripled the life expectancy of the design.

The company runs a tight ship when it comes to integrity of business ethics and quality of its products… I am confident that when measured against their competitors, we will find them to be our strongest partner in the FRP and engineered polymers space, on this continent.

AU

AU

NZ

NZ

UK

UK